The customer required a coloured print to be applied at intervals on a roll of material.

The Evolution system provided highly legible prints that could be easily changed in colour without having to flush the printer.

Two printheads, programmed by a single controller, were mounted on a custom made bracket to allow for the lines to be easily changed according to the width of the material.

After printing, the material entered a machine which folded the material and inserted a spring. As such, the speed of the material was not constant, with a lot of stop-start motion.

This issue was easly solved with the use of an encoder, which provided a speed signal to both printheads and enabled the printers to maintain a consistent width and distance apart – regardless of whether the material was stopped, accelerating or decelerating.

Material entering insertion machine

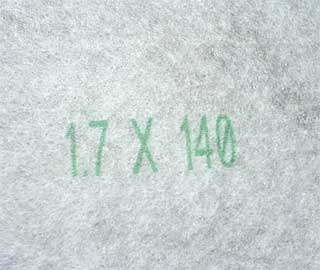

End result of print on part